PremierGroupManufacturing(Coventry)istransformingtheUKrailindustryfor thebetterwithitssheetmetalformingandfabrication

or 30 years Premier Group Manufacturing (PGM) has been

specialising in low volume and prototypesheet metal forming and fabrication.

Originally focused on the automotive industry, the West Midlands-based SME is now also well- established in the railways, with Bombardier, Network Rail and Alstom among its clients.

Greg Hodge, new business development manager, said: “Since being established in 1992 we have grown to become the market leader in the bespoke manufacturing of low series production panels, assemblies and prototypes spanning the international rail, automotive, aeronautical and defence industries.”

Skilled operators

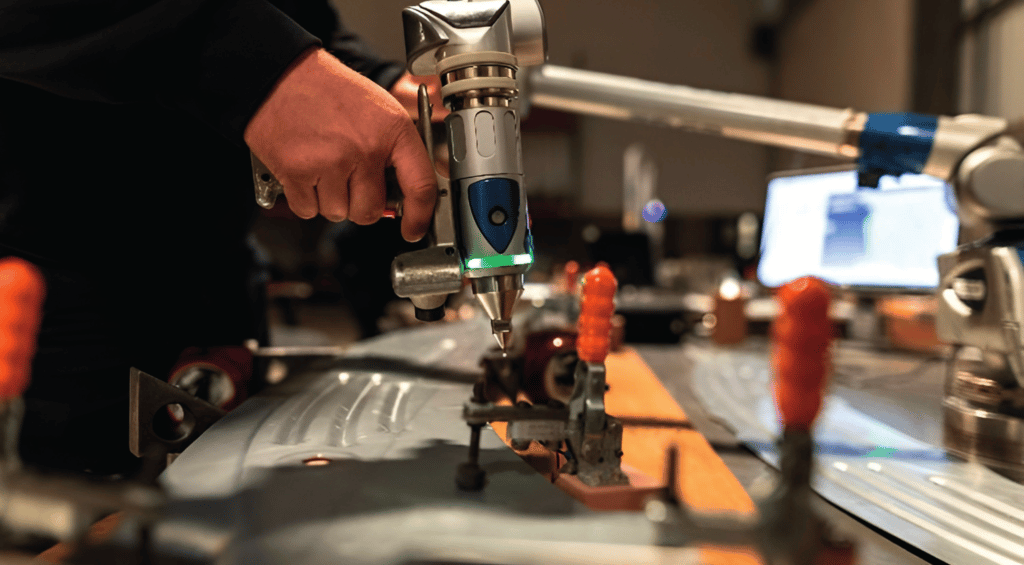

Greg added: “We are the definition of an SME with a headcount of 15 staff skilled in metal forming projects, including design for manufacture reviews of customers’ submitted projects where requested.

“The shop floor contains the heart of our capabilities with skilled operators able to manipulate metals (steel, aluminium etc) to form the intricate parts our customers require.”

All projects undertaken by PGM are done so covered by its recently updated ISO9001:2015 Certification and its written operating policies.

As well as metal forming, the experts also provide fabrication in Metal Inert Gas, Tungsten Inert Gas, and Cold Metal Transfer (CMT).

“CMT provides excellent control of the heat affected zones found with all welding work and can be critical to the success of the fabrication project,” added Greg.

“In addition, we provide powder coating and painting as well as metal surface treatments required by our customers’ projects through sub-contract local companies.”

All manufactured parts are CMM (coordinate measuring machine) inspected to its customer specified levels to provide full traceability of manufacture from the actual dimensional tolerancing of the manufactured parts to the detailed records of the materials used.

Greg concluded: “As our history stems from our automotive roots, we have a full appreciation and understanding of the importance of fast reaction to customer timings.

Brightfuture

“That alongside the offer of a full turnkey manufacturing capability, cutting-edge design, development, prototyping, manufacturing and logistics support, is why we’ve been so successful these past three decades and why the future looks bright.

“We apply this passion and knowledge to all our customers along with a do it right first-time philosophy. Our customers are our future and collaboration and innovation are the keys to ensuring a successful partnership.”